Behind the Scenes

Since 2018 Rock Up Group has been honing their training offering for the concrete polishing industry. Below features some behind the scenes of private training and assessment sessions around Australia and internationally.

Rock Up group would like to thank each and everyone we have worked with for your amazing energy, engagement feedback and most of all your trust in our process. It is a privilege to serve you within your businesses and inspiring to watch your ongoing successes.

Dynamic Floors – NSW

The test pad

Let the fun begin

Talking flat floors

Sample 1 at flood coat densifier, ready for Day 2

Sample 2 at flood coat densifier, ready for Day 2

Slab too soft yesterday so it got a dose of densi to strengthen and re, re-grout

200’s up

Sealer down on sample 2

We love samples

40 year old multiple finish samples

The Crew

CS Concrete Polishing – NSW

Good morning NSW! Hello CS Concrete Polishing

The Rock Up pre-start chat

Nice profile

The boys punching through 50 polish. 100m2 in 1hr with 2 machines

Densi going down

Touch of lithium to put some pop in

Flat edges

Today’s edge bandit

Blending in

Spot repair with machine at 200s. Real time. Real problems.

Ground work done. Now let’s get some glory!

Full face off!

Whatever the tool that created the damage is the tool that gets it out

The whole team working together Getting your team up to speed is what we do.

Checking out the handy work!

The boys

Final Buff

Happy crew!

JK Concrete Designs – Qld

Love that our work takes us to amazing places like this!

Dialling in the process for 1st cut

It took a whole morning to get to this stage, but gee did we tackle some theory/tooling/machine work and everything in between!

Talking tooling: 50/60 or 60/80?

Pre-densi before grout

Beautifully grouted edges

Loves the whiteboard…

100s coming up

Lick coat 200s

400 to 1500s - boom!

Gloss & DOI readings!

Virtscapes – WA

The crew 2022

Custom Training 2022 - 200 pass

Edges

1500s

Finished shot 2022

Protection is key

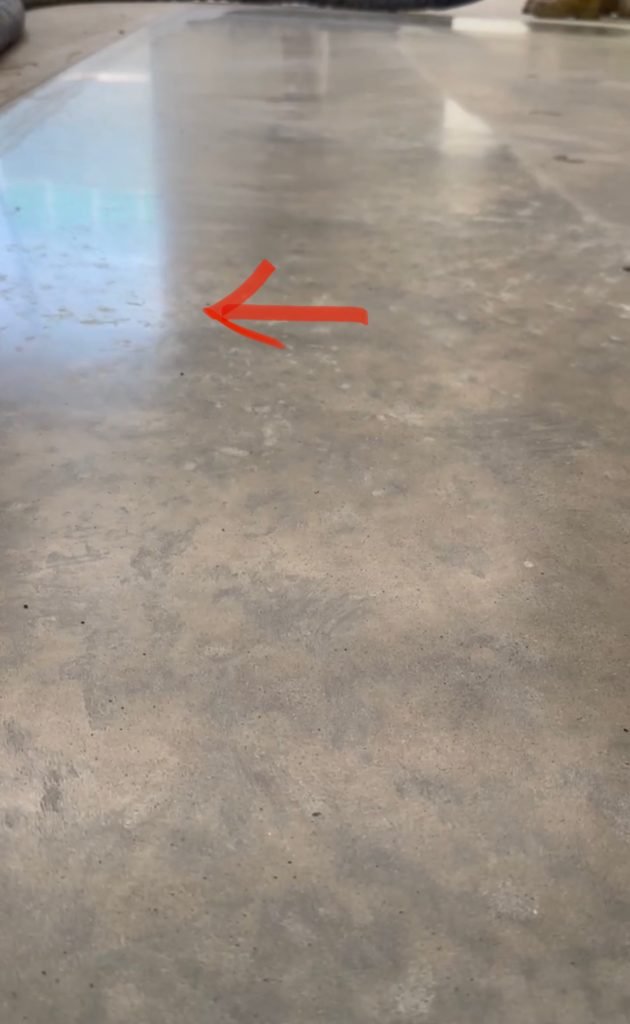

2023 - the brief was to take the boys through a dry process for an industrial surface polish

Quick industrial sample (dry process)

Conc not placed for this finish. Communication is key if you find yourself find yourself in this situation